For precision parts, processing is very strict, and the processing procedures include cutting in and out. There are specific requirements for size and accuracy, such as 1mm plus or minus micrometers, etc. If the size is too large, it will become waste. At this time, it is equivalent to reprocessing, which is time-consuming and laborious, and sometimes even makes the entire processed material scrapped.

This has caused an increase in cost, and at the same time, the parts are definitely unusable.

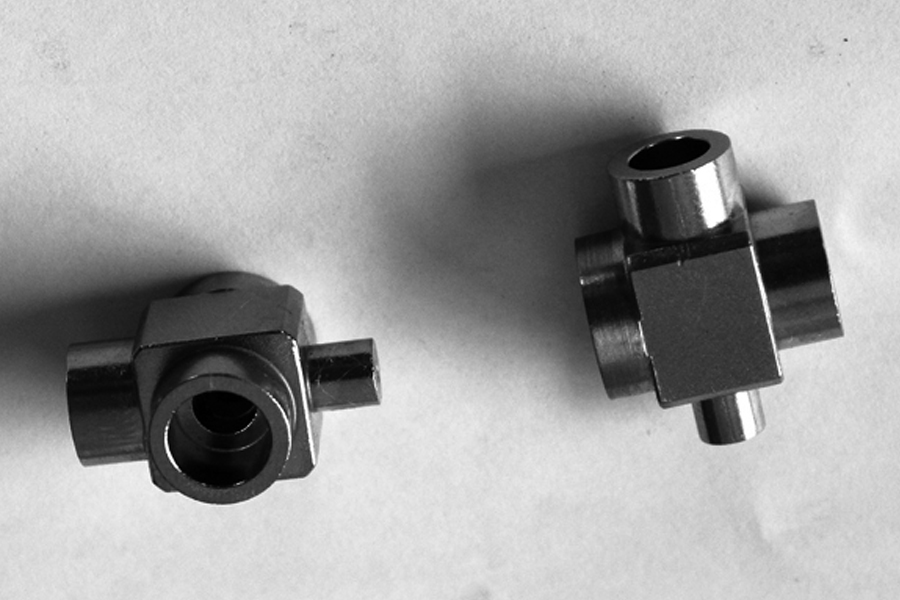

The processing of precision parts is mainly based on the size requirements, such as the diameter of the cylinder, there are strict requirements, and the positive and negative errors are within the specified requirements to be qualified parts, otherwise they are unqualified parts; the length, width and height are also specific and strict Requirements, positive and negative errors are also specified, such as an in-line cylinder (take the simplest basic component as an example). If the diameter is too large and exceeds the allowable range of error, it will cause the situation that it cannot be inserted. If the diameter is too small and exceeds the lower limit of the allowable negative value of the error, it will cause the problem of too loose and weak insertion. These are unqualified products, or the length of the cylinder is too long or too short, which exceeds the allowable range of error. They are all unqualified products. They must be discarded or reprocessed, which will inevitably increase the cost.

The above are the requirements for precision parts processing, which is the most important size problem. It must be processed strictly in accordance with the additional drawings. The actual size of the processing will definitely not be exactly the same as the theoretical size of the drawing, but as long as the processing size is within the error All qualified parts are within the allowable range. Therefore, the requirement for precision parts processing is to process in strict accordance with the theoretical dimensions.

The second is advanced precision parts processing equipment and testing equipment. Advanced processing equipment makes it easier to process precision parts, with higher precision and better results. Testing equipment can detect parts that do not meet the requirements, so that all products sent to customers can truly meet the requirements.

- 1. At the beginning of building or renting the house of precision machining factory, you should choose a building with Class I or II fire resistance, and you cannot build other suggested buildings inside the workshop, especially some simple buildings that are not fire resistant.

- 2. For oil rags, oil cotton yarn and other flammable materials used in normal processing. They should be put in a covered metal tube (box) and processed every day.

- 3. It is strictly prohibited to use gasoline, alcohol, etc. on the machine tool in the workshop. The remaining oil after washing the precision parts should not be placed randomly, even if it is to be placed, it should be placed in a place with fire prevention facilities, and should be poured into a container at a designated location for unified disposal.

- 4. Do not store large amounts of gasoline in the workshop. The storage capacity of engine oil and kerosene should not exceed the daily consumption. Generally, the required oil is collected according to daily needs. And store it in a covered iron bucket. If the storage capacity is large, a special oil storage room should be set up. No combustibles should be stored in the oil storage room, and the indoor ventilation should be kept good. The electrical switch should be installed in the outdoor distribution box. And regular maintenance and inspection of electrical appliances, strive to be foolproof.

- 5. Smoking must be banned in the production workshop. This is very important. Often a small cigarette butt can cause irreparable losses. If you have to smoke, you can concentrate on the smoking area.

- 6. If you need to perform open flame welding and cutting operations in the workshop, you should first check the surrounding environment, remove the surrounding combustibles, and use refractory materials to shield the nearby machine tools. Simultaneously. A person must be appointed to be responsible for observation and supervision. After the operation is over, the remaining fire should also be checked and eliminated.

- 7. The electrical equipment of the machine tool must be inspected and maintained regularly, and hidden dangers must be eliminated in time, and it must not be operated with luck. Installation, dismantling, maintenance, and commissioning must be performed by professional plumbers in accordance with regulations. All metal shells of electrical equipment should be reliably grounded.

The above are mostly sorted out by the editor based on the problems encountered by the company employees in their work practices. This is just a part, it is definitely not the whole, if you are interested, you can organize it together.